- TOSIZE.ie

- Wood and wooden sheets

- Timber boards

Timberboard Pine light

Product information

- Warps less than solid wooden planks

- Easy to lacquer and/or stain

- Warm, neutral look

- Flat and ready-to-use surface

- This wood warps: planks can warp

Description

Due to its light weight, pinewood is suitable for many purposes. This type of wood is often found in tables, cupboards, bookshelves and TV furniture. You can easily refurbish a piece of furniture with it, such as replacing a tabletop or desktop. Its natural and warm appearance adds charm to any interior.

Configure Timberboard Pine light

How convenient is that

Product information

- Warps less than solid wooden planks

- Easy to lacquer and/or stain

- Warm, neutral look

- Flat and ready-to-use surface

- This wood warps: planks can warp

Description

Due to its light weight, pinewood is suitable for many purposes. This type of wood is often found in tables, cupboards, bookshelves and TV furniture. You can easily refurbish a piece of furniture with it, such as replacing a tabletop or desktop. Its natural and warm appearance adds charm to any interior.

Product properties

Applications

- Tables

- Bookcases

- Furniture

- Bookshelves

Order cut-to-size timberboard pine light sheets online

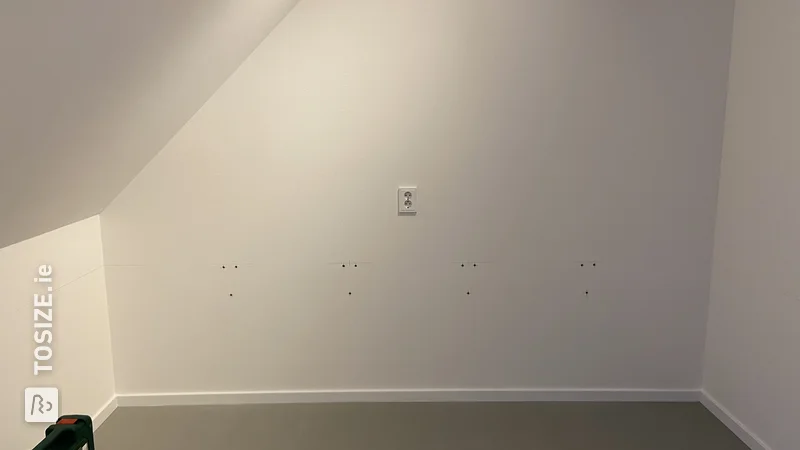

Easily order cut-to-size timberboard pine light sheets online. Solid timber panels can be cut or milled to size into various shapes. The most commonly chosen shape is a rectangle, but we also mill circles, ovals, hexagons or even parallelograms for you. Do you want to have your do-it-yourself project neatly finished? Then choose one of the available (edge) finishes.

Solid light pine timberboard: what is it?

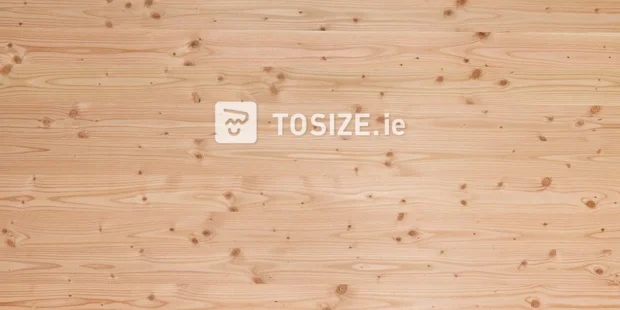

Pine light is a very popular sheet material in our range. The tough and natural look makes these light pine boards a popular choice. Solid pine is yellowish, and with the alternation of small and larger knots, this makes it an uninhibited wood species. Compared to pine dark, pine light is lighter in colour. The ideal type of wood for making Scandinavian-style furniture. Compared to other solid wooden sheets in our range, pine is relatively colourfast. The solid sheet material is made up of slats. Slats are small wooden planks made entirely of pure wood. In order to be able to make a sheet of a larger size, several slats are combined into one large sheet. This results in a very solid and strong sheet. Keep in mind that no slat has the same appearance. The wood structure and colour of each slat is unique and can therefore also deviate from the image.

Wood can be divided into the categories of hardwood and soft wood. Hardwood comes from deciduous trees and softwood from coniferous trees. Pinewood is a light-coloured coniferous species. Coniferous wood, or softwood, is relatively less strong than hardwood. This makes the material easy to work with.

The light pine timberboards in our range are of high quality. This can be deduced from the visual grading. The visual grading is indicated by letters, often a combination of two letters with a separator between them. This can be found in the product name or the product properties. The first letter represents the top of the sheet, the second for the bottom or backside. A/B thus describes the appearance of the top and bottom of the sheet. A is the best visual grading a wood species can have, with the sheet being almost knotless. The underside has visual grading B, which means that the underside can have a somewhat coarser appearance.

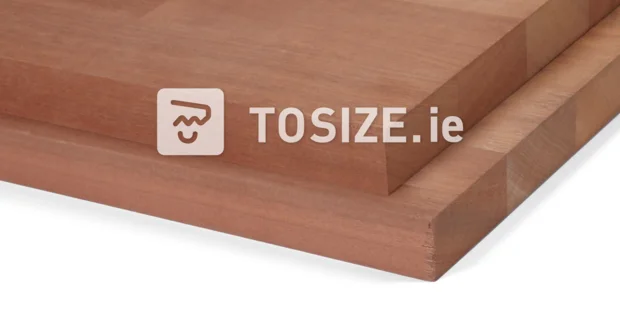

To achieve a solid pine panel, small planks are cut from the wood (slats), these are then glued through. This means that the slats are glued together with a flat side, without a specific joiner. To make a larger-sized board, several slats are glued together to make one large board. This results in a long and wide sheet consisting of several slats.

The result is a solid wooden sheet that is visibly composed of several small slats. These slats run in the longitudinal direction of the sheet. Keep in mind that no slat has the same appearance. The wood structure and colour of each slat is unique and can therefore also deviate from the image. Our solid sheets are interior bonded, which means that the material can only be used indoors.

The direction of the wood grain

Timberboard has a visible wood grain. The wood grain pattern always runs in the longitudinal direction. When sawing the sheet, we maintain that the longitudinal dimension is also the longitudinal direction of the wood grain. So be careful when filling in the measurements, so that the flames of the wood grain all run in the right direction!

Quality grading with timberboard

Timberboard comes in different qualities. This does not mean that the sheet is more or less strong, it indicates the quality of the appearance of the sheet . The quality can be found in the product properties. More information about the visual grading below.

| Lumber Quality Indication | |

|---|---|

| A | Uniform colour. No knots and no heartwood allowed. |

| B | Small colour nuances permitted. Tassels and heartwood may be present. |

| C | Large colour nuances permissible. Tassels and heartwood are present. |

Read here more about the quality of timberboards.

Available thicknesses of timberboard pine light

The available thicknesses can be easily selected via the product configurator. We have the following thickness(es) available: 18 mm, 28 mm and 40 mm.

Machining timberboard pine light

Timberboard pine light is easy to assemble, by bonding it. Also finish pine light with a clear lacquer, varnish or stain. Because of its soft structure, this type of wood is sensitive to impact. Always sand solid wooden sheets with a fine grain before you start working with it. The sanding of light pine timberboard provides a beautiful end result, so the details of the grain pattern stand out even more. Which benefits the robust, cool sheet.

Finishing the timberboard enhances the protection and, simultaneously, the moisture-resistant properties of the material. Like all solid boards, light pine timberboard can warp under varying temperatures and humid conditions. If you want to saw or mill the material, keep in mind that it may splinter. When assembling the sheets, use screws with a long thread and wide diameter to avoid splitting as much as possible. Finally, we recommend that only stainless steel is used for bonding with metal to prevent discolouration on the wood.

Pinewood, like several other solid wooden sheets, will warp with temperature differences and in humid conditions. This can cause the sheets to warp during transport or installation in the house. After the sheet has been sanded, it is important to treat the light pine timberboard well with a lacquer, stain or oil.

Specific applications of timberboard pine light

Due to its light weight, pinewood is suitable for many purposes. This type of wood is often found in tables, cupboards, bookshelves and TV furniture. You can easily refurbish a piece of furniture with it, such as replacing a tabletop or desktop. Its natural and warm appearance adds charm to any interior.

Alternatives to light pine timberboard

Is timberboard pine light not the right type of wood for your project? Check out our other solid wood species here as well:

Recommended combinations