- TOSIZE.ie

- Wood and wooden sheets

- Board

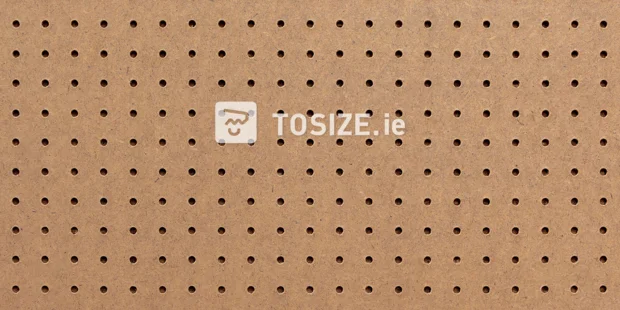

Hardboard

Product information

- Wide application indoors

- Light board material

- Easy to process

- Easy to paint

- Ecological product due to production without glue

- Not suitable for outdoor use

- This thin board material ripples.

Description

Hardboard is a thin board material that is mainly used for rear walls of cupboards. But hardboard also comes into its own as an underlay and packaging material. A sheet of hardboard is smooth on one side and has a copper-mesh net structure on the other. This material is only suitable for indoor projects.Hartplatten sind dünne Platten, die hauptsächlich für Schrankrückwände verwendet werden. Aber auch als Unterlage und Verpackungsmaterial kommen Hartfaserplatten zum Einsatz. Eine Hartfaserplatte ist auf der einen Seite glatt und hat auf der anderen Seite eine Netzstruktur aus Kupfergeflecht. Dieses Material ist nur für Projekte in Innenräumen geeignet.

Configure Hardboard

How convenient is that

Product information

- Wide application indoors

- Light board material

- Easy to process

- Easy to paint

- Ecological product due to production without glue

- Not suitable for outdoor use

- This thin board material ripples.

Description

Hardboard is a thin board material that is mainly used for rear walls of cupboards. But hardboard also comes into its own as an underlay and packaging material. A sheet of hardboard is smooth on one side and has a copper-mesh net structure on the other. This material is only suitable for indoor projects.Hartplatten sind dünne Platten, die hauptsächlich für Schrankrückwände verwendet werden. Aber auch als Unterlage und Verpackungsmaterial kommen Hartfaserplatten zum Einsatz. Eine Hartfaserplatte ist auf der einen Seite glatt und hat auf der anderen Seite eine Netzstruktur aus Kupfergeflecht. Dieses Material ist nur für Projekte in Innenräumen geeignet.

Product properties

Applications

- Levelling floors

- Rear side of cabinets

- Furniture panelling

- Packaging

Ordering customised hardboard panels online

Order cut-to-size hardboard and other Wood and wooden sheets easily online. Hardboard is easily cut to size and machined. Because it is a thin material, this board material should always be fixed. The material undulates very quickly.

Hardboard: what is it?

Hardboard is a thin board material that can be used, among other things, for back walls of cupboards or other furniture, for levelling floors and as packaging material. But hardboard can also be used for finishing walls and ceilings. Like MDF, hardboard belongs to the family of fibreboards. Due to the structure of the press in which the wood fibres are compressed, hardboard has a smooth and a rough top layer with a copper mesh structure. During the process, the wood fibres are wetted and pressed under high pressure and temperature. As a result, no glue is needed to hold the fibres together. It is only suitable for indoor applications, as it has a suction effect and is therefore not resistant to moisture.

Hardboard is a constructional board. This means that this board material needs the necessary finishing before it can be used for visible work.

Available thicknesses of hardboard

With us, you can order high-quality customised hardboard in various thicknesses. You can easily specify the desired thickness in the product configurator. In this way, you can be sure that the board material meets your requirements: both the format and the thickness of the material. The following thicknesses are available: 3 mm.

Machining of hardboard sheets

The board consists of wood fibres that are compressed under high pressure. This makes the material easy to process. When milling or sawing, this board material does not splinter. For mounting, you can choose to nail or screw this material.

Are you going to paint this board? Finish the edges with an edge sealer and then sand and paint neatly. Bear in mind that only one side can be finished. It is also important to degrease the board properly.

Specific applications of hardboard

Hardboard is an easy-to-process sheet material used for various interior panelling applications. Hardboard is an ideal product for packaging, for levelling floors and as a back wall for various types of furniture or cupboards. The homogeneous structure makes this board, in comparison to other board material, less sensitive to shrinkage and expansion in changing temperatures. Hardboard is not suitable for use in damp rooms or outdoors. It is important to always fix hardboard, otherwise the material will undulate.

Alternatives to standard board

Is hardboard not the right wood type for your job? Looking for board with a grain? Then go for poplar plywood. Do you want board material that can be used outdoors? Then take a look at phenolic plywood, MDF tricoya or multiplex okoumé.

Recommended combinations